Sodiceram Explained: Meaning, Uses, and Real-World Impact

Introduction

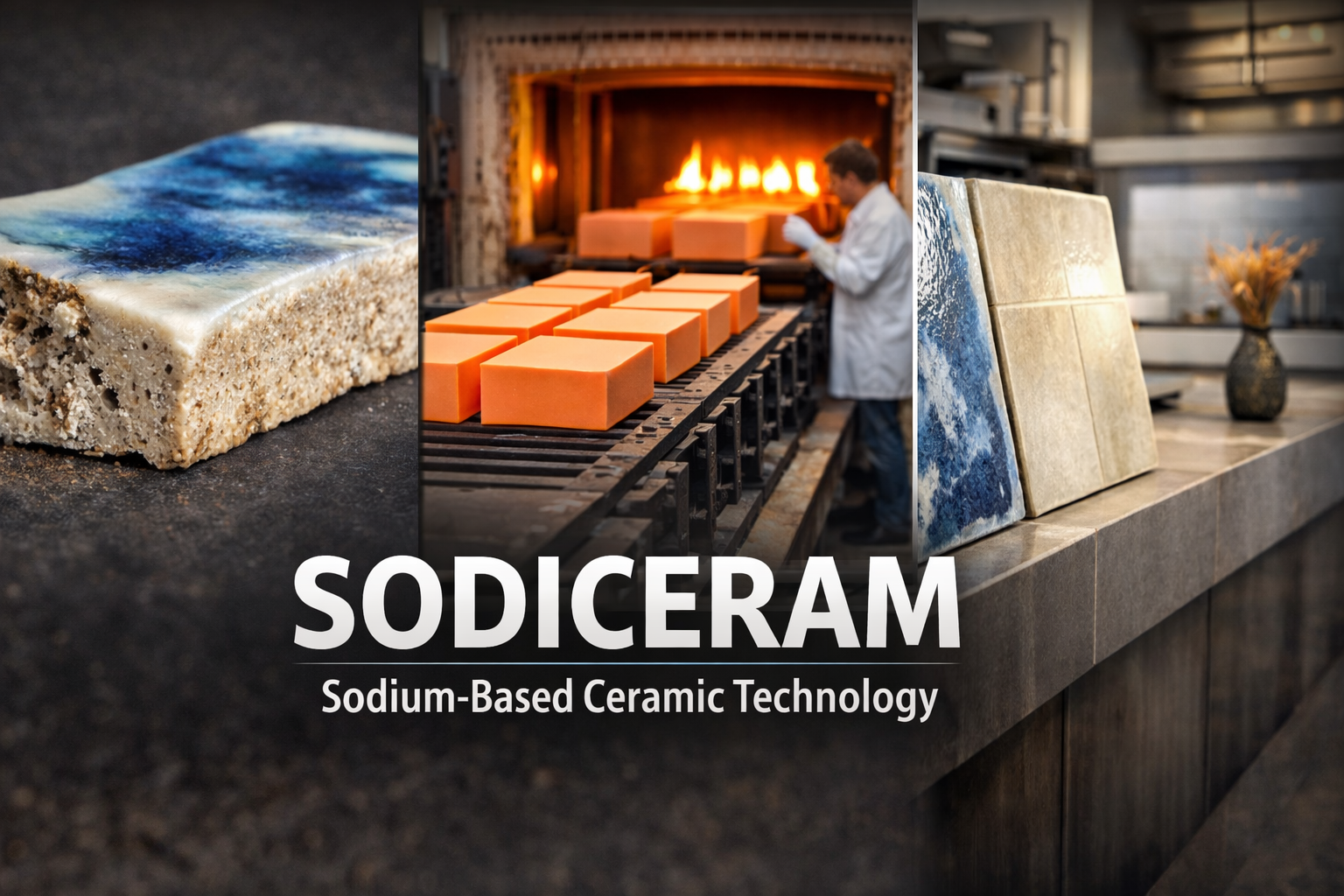

The term sodiceram may sound technical at first, yet it represents a fascinating and increasingly relevant concept in the world of ceramics, materials science, and industrial design. At its core, sodiceram refers to ceramic materials and processes that rely on soda-based compounds or sodium-rich formulations to achieve specific physical, chemical, and aesthetic properties. From architectural surfaces to advanced industrial components, sodiceram plays a quiet but meaningful role in shaping modern products we use every day.

This article offers a deep, practical exploration of sodiceram—what it means, how it works, and why it matters across multiple industries. You’ll learn about its origins, material behavior, production methods, applications, advantages, limitations, and future potential. Whether you’re a student, designer, engineer, manufacturer, or simply curious, this guide is designed to give you clear, original, and usable insight into sodiceram and its broader relevance.

Will You Check This Article:Rolex Express: Speed, Trust, and Luxury Combined

What Is Sodiceram?

Sodiceram is a broad term used to describe ceramic materials that incorporate sodium-based compounds—often soda ash (sodium carbonate) or sodium silicates—during formulation or firing. These compounds act as fluxes, meaning they lower the melting point of ceramic mixtures and influence texture, strength, and finish.

Unlike traditional ceramics that rely heavily on high-temperature firing alone, sodiceram-based systems emphasize chemical balance. Sodium compounds help particles bond more efficiently, allowing manufacturers to control density, porosity, and surface smoothness with greater precision.

In simple terms, sodiceram is not a single product but a material philosophy. It represents a category of ceramics engineered for performance, efficiency, and adaptability rather than just tradition.

The Origins and Evolution of Sodiceram

The roots of sodiceram can be traced back to early glassmaking and pottery, where sodium-rich ashes were accidentally discovered to improve melting behavior. Ancient artisans didn’t know the chemistry, but they recognized the results: smoother surfaces, brighter finishes, and reduced firing times.

As industrial ceramics evolved in the 19th and 20th centuries, sodium compounds became intentional additives. Engineers realized they could fine-tune ceramic properties by adjusting soda content. This marked the transition of sodiceram from craft knowledge to controlled industrial science.

Today, sodiceram principles are used in both mass manufacturing and specialized applications, bridging ancient techniques and modern engineering.

Key Material Characteristics of Sodiceram

One of the reasons sodiceram remains relevant is its distinct combination of material properties. These characteristics make it adaptable across many sectors.

Physical and Chemical Traits

Sodiceram materials typically demonstrate controlled vitrification, meaning they become glass-like at lower temperatures than many traditional ceramics. This improves energy efficiency and consistency during production.

They also tend to offer balanced hardness and toughness. While not always as extreme as advanced technical ceramics, sodiceram formulations strike a practical middle ground between strength and workability.

Functional Advantages

Sodium compounds enhance ionic mobility during firing. This allows particles to rearrange more easily, reducing internal stress and cracking. The result is a more predictable, reliable ceramic product.

Below is a simplified comparison table highlighting typical characteristics.

| Property | Traditional Ceramic | Sodiceram-Based Ceramic |

|---|---|---|

| Firing Temperature | Very high | Moderately high |

| Energy Efficiency | Lower | Higher |

| Surface Finish | Variable | More uniform |

| Porosity Control | Limited | Highly adjustable |

How Sodiceram Is Manufactured

Sodiceram production follows familiar ceramic steps but with key chemical distinctions that affect outcomes.

Raw Material Selection

Manufacturers begin with clays, feldspars, and silica, then introduce sodium compounds in carefully measured amounts. Too little soda reduces effectiveness; too much can weaken structure. Precision matters.

Shaping and Forming

Once mixed, the material is shaped using pressing, extrusion, or casting methods. Sodiceram bodies often respond well to forming because sodium improves particle lubrication during shaping.

Firing and Transformation

During firing, sodium compounds act as fluxes. They promote partial melting, allowing particles to fuse at lower temperatures. This stage defines the final strength, color, and texture of sodiceram products.

Applications Across Industries

Sodiceram is not confined to one niche. Its adaptability allows it to serve diverse fields, from construction to technology.

Architecture and Interior Design

In architectural ceramics, sodiceram enables smoother tiles, consistent glazing, and reduced defects. Designers value its ability to produce clean lines and refined finishes at scale.

Industrial and Technical Uses

In industrial environments, sodiceram materials are used for electrical insulators, protective linings, and wear-resistant components. Their balance of durability and manufacturability makes them cost-effective.

Art, Craft, and Creative Work

Artists appreciate sodiceram for its responsiveness in the kiln. Glazes flow more predictably, and surfaces develop subtle depth without excessive firing risk.

Environmental and Energy Considerations

One overlooked advantage of sodiceram lies in sustainability. Because sodium-based fluxes reduce firing temperatures, they lower overall energy consumption. Over large production runs, this difference becomes significant.

Additionally, some sodiceram formulations incorporate recycled glass or industrial byproducts containing sodium. This reduces raw material extraction and diverts waste from landfills.

While sodiceram is not inherently “green,” its chemistry enables more responsible production when applied thoughtfully.

Sodiceram vs. Other Ceramic Systems

To understand sodiceram’s value, it helps to compare it with other ceramic approaches.

Compared to High-Alumina Ceramics

High-alumina ceramics excel in extreme conditions but require intense energy and cost. Sodiceram sacrifices some extreme performance in exchange for efficiency and versatility.

Compared to Glass-Ceramics

Glass-ceramics offer precision and translucency, yet they can be brittle and expensive. Sodiceram sits between traditional ceramics and glass-ceramics, combining durability with aesthetic control.

This middle-ground positioning explains why sodiceram remains popular in both functional and decorative contexts.

Common Misconceptions About Sodiceram

Despite its long history, sodiceram is often misunderstood.

One common myth is that sodium automatically weakens ceramics. In reality, controlled sodium content improves bonding and reduces defects. Weakness only occurs when formulations are poorly balanced.

Another misconception is that sodiceram is outdated. On the contrary, many modern ceramic innovations build on soda-based chemistry, especially where efficiency and scalability matter.

Real-World Case Example

Consider a mid-sized tile manufacturer struggling with inconsistent glaze quality and high fuel costs. By adjusting formulations to incorporate sodiceram principles, the company reduced firing temperatures by nearly 8%. Defect rates dropped, surface uniformity improved, and production timelines shortened.

This example highlights sodiceram’s quiet power: small chemical changes producing large operational benefits.

Challenges and Limitations

Sodiceram is not a universal solution. Excess sodium can cause deformation or glaze instability. Long-term exposure to moisture may also affect certain sodium-rich ceramics if not properly sealed.

Successful use of sodiceram depends on expertise, testing, and process control. It rewards precision but punishes shortcuts.

The Future of Sodiceram

Looking ahead, sodiceram is likely to evolve alongside smart manufacturing and material science. Researchers are exploring nano-scale sodium distribution, hybrid ceramic-glass systems, and digitally controlled firing profiles.

As industries seek efficiency without sacrificing quality, sodiceram principles are expected to gain renewed attention rather than fade away.

Conclusion

Sodiceram represents more than a material choice—it reflects a strategic approach to ceramic design and production. By leveraging sodium-based chemistry, manufacturers and creators gain flexibility, efficiency, and control over final outcomes.

From architecture to industry and art, sodiceram continues to prove its relevance through adaptability and performance. Understanding its principles allows professionals and enthusiasts alike to make better material decisions.

The takeaway is simple: when chemistry, craftsmanship, and intention align, sodiceram becomes a powerful tool rather than just another ceramic variation.

Frequently Asked Questions (FAQs)

What does sodiceram mean in simple terms?

Sodiceram refers to ceramic materials that use sodium-based compounds to improve melting, bonding, and surface quality during production.

Is sodiceram a product or a process?

It is better understood as a material approach rather than a single product, influencing how ceramics are formulated and fired.

Are sodiceram materials durable?

Yes, when properly formulated, sodiceram ceramics offer strong durability suitable for both decorative and industrial uses.

Can sodiceram reduce manufacturing costs?

In many cases, yes. Lower firing temperatures and improved consistency can reduce energy use and material waste.

Is sodiceram suitable for artistic ceramics?

Absolutely. Many artists value sodiceram-based bodies and glazes for their predictability and expressive surface results.